Pressure Sensing Solutions Inspired by Your vision

Products

Products

Search off-the-shelf, customizable, or full-custom design to manufacturing pressure sensors.

Solutions by Market

Solutions by Market

Discover the wide range of industry applications for our pressure sensing solutions.

Engineering Assets

Engineering Assets

Access all the engineering resources to help with design, selection, and integration of our pressure sensors.

About Us

About

Learn about the industry leader in the designing and manufacturing of ultra low pressure sensors.

The Pressure Sensor Manufacturer

Amphenol All Sensors is the leader in design to manufacturing of low and ultra-low pressure sensors. Our product line is notable for its high accuracy, repeatability, and a wide range of customizable features. Pressure ranges are available as low as 0.25 in H2O and as high as 150 PSI.

New Products Spotlight

FEATURED BRANDS

ELVX Series: Digital Pressure Sensors

The ELVX Digital Pressure Sensor Series are leadless with dual die configuration which provides best-in-class stability for low and ultra-low pressure applications.

Features:

- ± 0.5 inH2O to ± 60 inH2O

- Gage or Differential Pressure

- Precision ASIC Conditioning

- Digital I2C and SPI Options

- 3.3V and 5V Supply Voltage Options

- PCB Surface Mount

- Improved Warm-up Stability

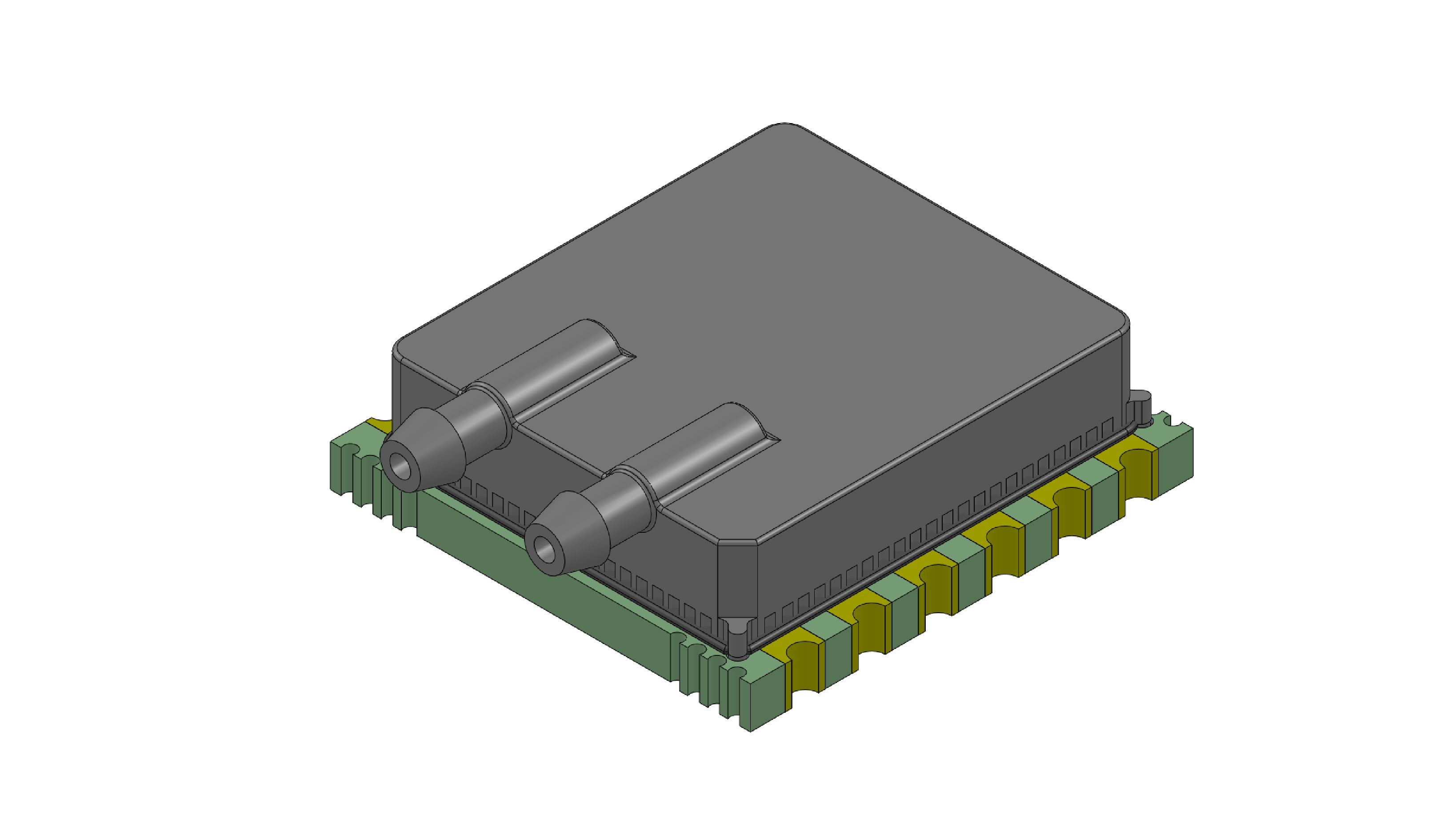

AUAV High Accuracy Dual Air Speed & Altitude Sensor

The Amphenol All Sensors AUAV series is a dual sensor specifically designed for the demanding requirements of Unmanned Aerial Vehicles (UAVs). This sensor combines a high-accuracy differential pressure sensors with Baraometric (Altitude) pressure sensor in a single package.

Features:

- Compact and Lightweight Dual Sensors in a Single Package

- Simultaneous Measurement of Windspeed and Altitude (Barometric) Sensing

- 18-bit high resolution I2C or SPI Output Interfaces for both sensors

- -40°C to +85°C Operating Temperature Range for Harsh environments

- Surface Mount Design compatible with SMT Automated Assembly

- 3.3 or 5.0 Vdc supply voltage

- Low power option available (standby <1uA)

- Barbed pressure ports

- Fully Customizable for OEM applications

- Learn about the AUAV Evaluation Board

All Sensors Evaluation Kit (EK-02) Release

The Amphenol All Sensors Evaluation Kit is an essential tool for engineers and developers seeking to simplify the design, testing, and validation process of All Sensors’ products.

Features:

- Simplified Testing of Analog & Digital Sensors

- Quick Setup with ZIF Socket for Instant Electrical Connection

- Seamless Data Capture to CSV Files

- Optional Adapters for Leadless & SMT Packages

- Standard 4mm Connectors

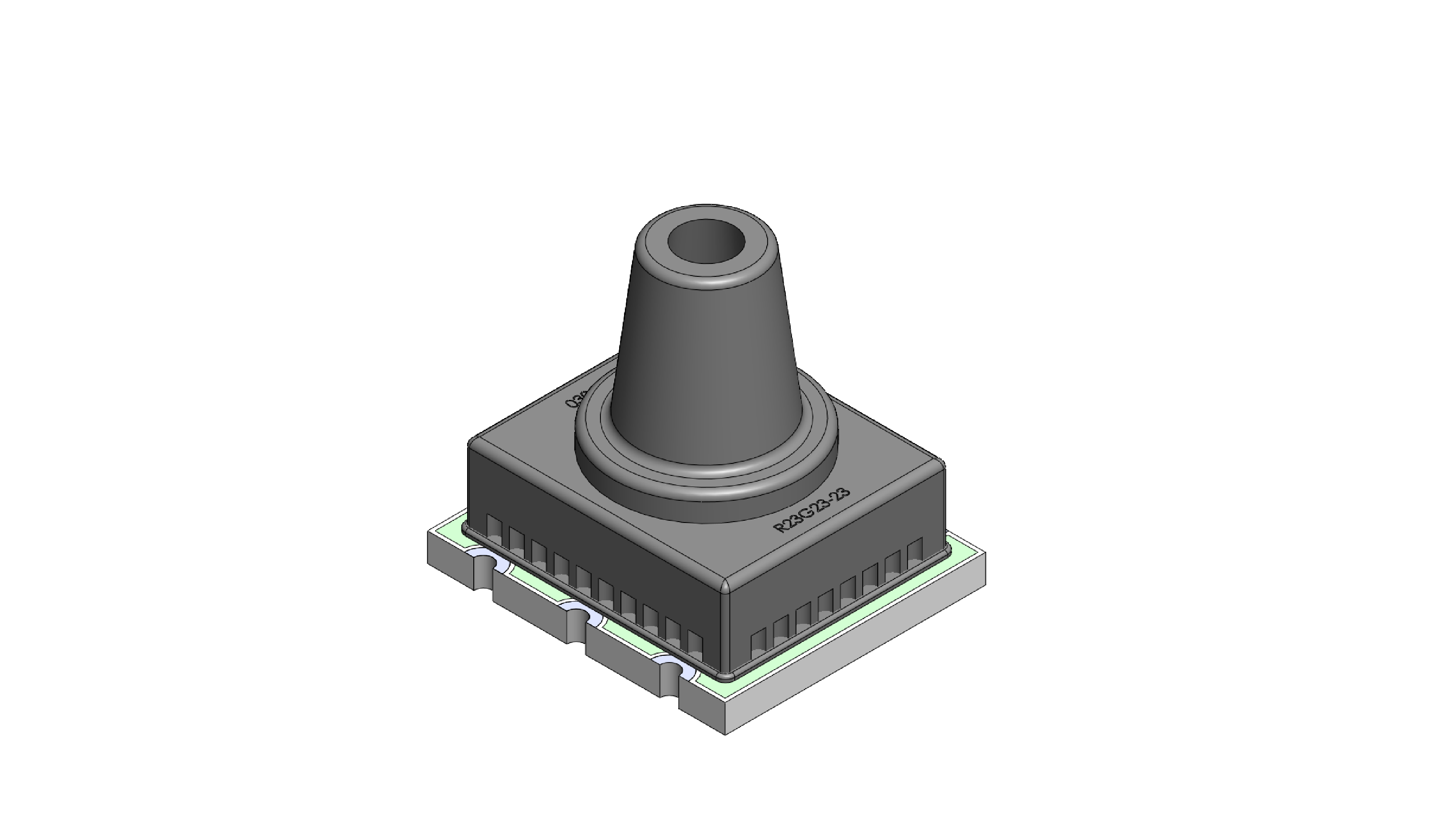

BFTM Series Basic Pressure Sensors

The Amphenol All Sensors BFTM series leverages proprietary technology to minimize size while maintaining superior performance. These sensors significantly reduce output offset errors caused by position sensitivity, packaging stress, and long-term drift compared to conventional silicon sensors.

Features:

- Ultrastable and Compact Design

- Enhanced Accuracy

- Optimized packaging for high common mode & low differential pressure monitoring

- Combined Absolute and Differential pressure in single package

- RoHS Compliant

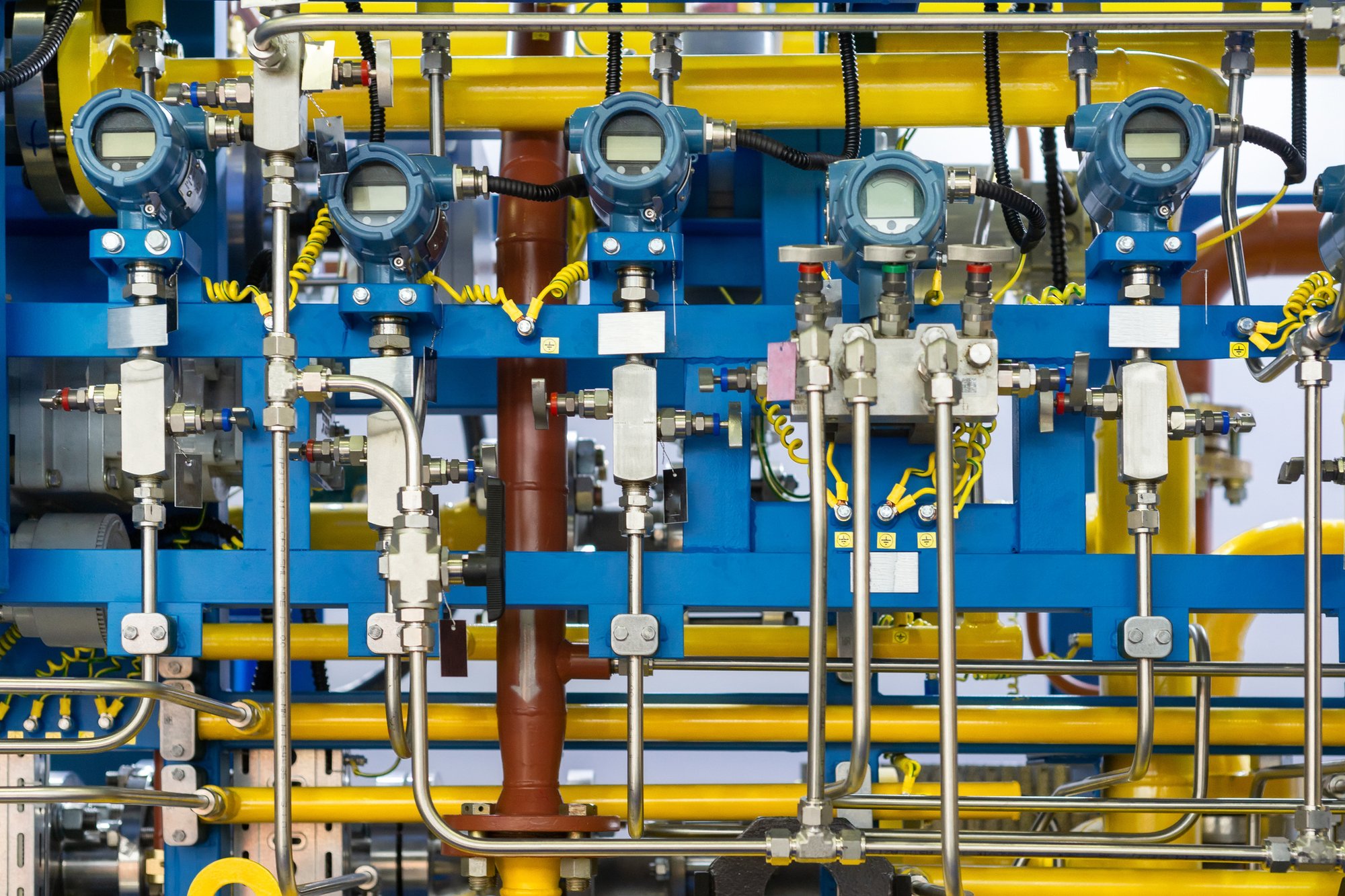

Low Pressure Sensor Solutions by Industry

Explore how Amphenol All Sensors low and ultra-low sensors market-specific expertise provide solutions across markets

Expert Low Pressure Sensors Applications

%201.webp?width=813&height=429&name=unnamed%20(18)%201.webp)

DRONES

With our state-of-the-art dual pressure sensor combining both Barometric (Altitude) and Air Speed Sensing in a single PCB mountable package and sensors to detect headwind and, cross-axis wind, we are helping UAVs (drones) increase productivity, reduce risk, and maintain payload stability.

Learn More%201.webp?width=813&height=429&name=unnamed%20(19)%201.webp)

CRITICAL CARE EQUIPMENT

In the critical realm of respiratory support equipment, such as ventilators, transport ventilators, and anesthesia machines, our pressure sensors play an essential role in ensuring patient safety and effective treatment. These sensors are key in providing precise control of airway pressure, a factor that is vital for the safe and effective support of patients with respiratory challenges.

Learn More

Contact our Team of Experts Today

Featured Products

-

AUAV Series AUAV Series

Dual Sensors in a Single Package, Simultaneous Measurement ...

Learn More -

AABP Series AABP Series

AABP Series- Coming Soon!

Learn More -

MLDX Series MLDX Series

5 inH2O to 100 PSI Pressure Ranges, matched pressure port ...

Learn More -

.png?width=250&height=250&name=ELVH%20(1).png)

ELVH Series ELVH Series

0.5 up to 30 inH2O and 1 up to 150 psi and 100 mbar up to ...

Learn More -

DLHR Series DLHR Series

0.5 to 60 inH2O, 1.68V to 3.6V Supply Voltage

Learn More -

Custom Sensor Solutions Custom Sensor Solutions

Based on your unique application, a customizable or ...

Contact Our Team